NEWS

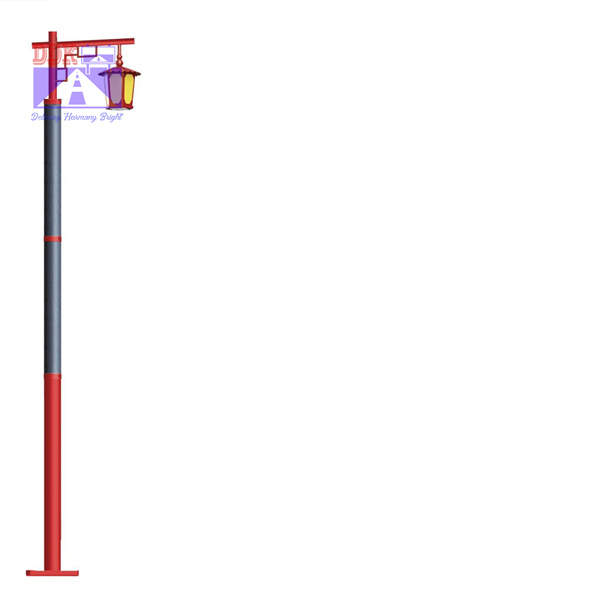

Road application scale of high pole lamp: Duyi square, station, ship port, freight yard, highway, stadium, overpass. High pole lamp manufacturers for your detailed introduction.

1. Light pole for octagonal or dodecagon cone rod body, by high strength steel plate after cutting, bending, automatic welding forming, general height of 25, 30, 35 and other specifications, intends to maximum wind resistance material dry up to 60 m/s, each specification by 3 to 4 sections of the plug. With flange steel chassis, 1 m to 1.2 m in diameter, 30 mm to 40 m thick.

2. The efficiency is mainly based on the frame mechanism, and the decorative materials are mainly steel pass and steel pipe, and the lamp pole and lamp plate are handled by hot dipping zinc.

3. Electric take-off and landing fragments are composed of electric motors, winches, three groups of hot-dip galvanized steel wire rope and cables. The lamp pole is installed inside the body and the lifting speed is 3 to 5 meters per minute.

4. The trivialization of guiding and unloading is caused by the guiding wheel and the guiding arm to ensure that the lamp plate will not fire and move horizontally in the lifting process, and ensure that the lamp plate can wither and be locked by the hook when the lamp plate is picked up.

5. Lighting appliances are divided into 6 -- 24 400 W - 100 W metal halide (white light), light projection, floodlight, computer time controller can be passive control turn on and off the lamp time and a small piece of lighting or full lighting,

6. Lightning protection: 1.5-meter-long lightning rod is installed on the top of the lamp, and a 1-meter-long grounding wire is installed on the underground root and bolted to the dark ground