NEWS

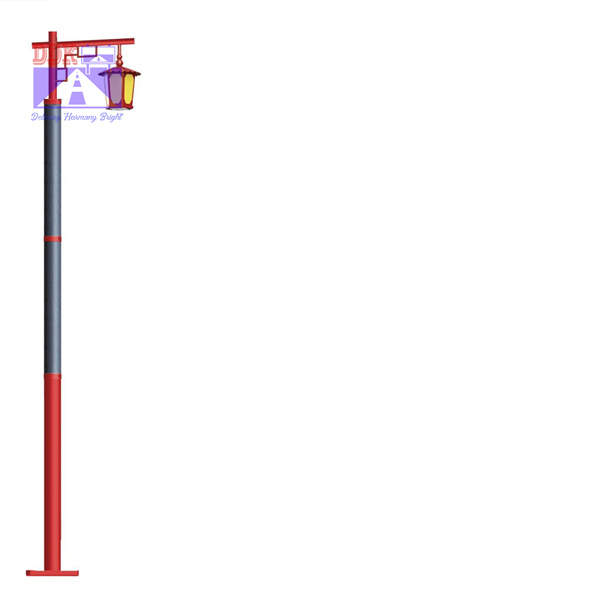

The reason why the high-pole light is called a high-pole light is because it is tall and has a lifting system. Let's follow the high-pole light manufacturer to learn more about it.

The electric lifting system of the high-pole light consists of an electric motor, a hoist, three groups of hot-dip galvanized steel wire ropes and cables. The light pole is installed in the body, and the lifting speed is 3 to 5 meters per minute. The lighting electrical system of the high-pole lamp is equipped with 6-24 400w-1000w metal halide (white light), floodlight, floodlights, and the computer time controller can automatically control the switching time of the lights and partial lighting or full lighting.

The flatness of the concrete pouring surface of the high pole lamp foundation should be less than 5mm/m to keep the embedded parts of the vertical pole as level as possible. The flange of the embedded part is 20~30mm lower than the surrounding ground, and then the reinforcement ribs are covered with C25 fine stone concrete to prevent water accumulation. The threads above the flange of the embedded anchor bolts are well wrapped to prevent damage to the threads. Correctly place the embedded parts of the monitoring pole according to the installation drawing of the embedded parts, and ensure that the extension direction of the support arm is perpendicular to the roadway (or as required by the engineer), and the anchor bolts are used as the main reinforcement.